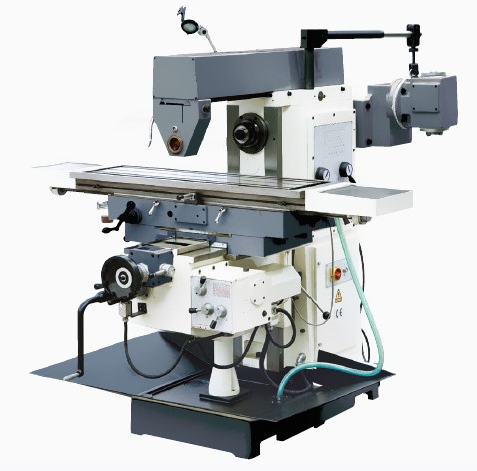

Mashiinka Milling VMC850 CNC Vertical

Sharaxaada Alaabta

2. Jiid nidaamka

Saddexda dhidib ee hagaha tareenada waxay qaataan tareenada toosan ee duuban ee la soo dhoofiyo, kaas oo leh awood yar oo firfircoon oo kacsan, dareen sare, gariir yar oo xawaare sare ku socda, ma jiro gurguurasho xawaare hoose, saxnaanta meelaynta sare, waxqabadka wadida servo ee wanaagsan, oo wanaajisa saxnaanta iyo xasiloonida saxda ah ee qalabka mashiinka.

Saddexda dhidib ee servo motor waxay si toos ah ugu xidhan tahay kubbadda saxda ah ee saxda ah iyada oo loo marayo isku xirka laastikada, yaraynta isku xirka dhexdhexaadka ah, garashada gudbinta nadiifinta, quudinta dabacsan, meelaynta saxda ah iyo saxnaanta gudbinta sare.

Z axis servo motor oo leh shaqo quful otomaatig ah, haddii ay dhacdo koronto la'aan, waxay si toos ah u xiri kartaa shafka mootada si ay u xajiso, si aysan u wareegi karin, door ka ciyaarto ilaalinta amniga.

3. Kooxda dunta

Kooxda udubdhexaadka ah ee ugu weyn waxaa soo saara soo saaraha xirfadlaha ah ee Taiwan, oo leh saxnaanta sare iyo qallafsanaanta sare. Sidi P4 fasalka dunmiilaha gaar ah, set oo dhan ee kulanka dunidu hoos xaaladaha heerkulka joogto ah, ka dib markii la dhammeeyo ee sixitaanka dheelitirka firfircoon iyo imtixaanka socda, hagaajinaysaa set oo dhan nolosha adeegga dunidu iyo isku halaynta sare.

Spindle-ku wuxuu ogaan karaa nidaaminta xawaaraha bilaa-tallaabista ee kala duwanaanshaha xawaaraha, dunta dunta waxaa gacanta ku haya matoorka ku dhex-dhisan encoder, kaas oo xaqiijin kara jihaynta dunta iyo shaqada taabasho adag.

4. Maktabadda mindida

Maktabadda aaladda robot-ka ayaa lagu rakibay dhinaca tiirka. Madaxa gooyuhu waa uu wadaa oo meeleeyaa habka CAM rollerka marka la bedelayo qalabka. Kadib dunidu gaadho booska beddelka aaladda, aaladda wax-ka-beddelka qalabka (ATC) waxay dhammaystiraysaa soo celinta mindida iyo quudinta mindida.

5. Goynta habka qaboojinta

Ku qalabaysan bamka qaboojinta qulqulka weyn iyo haanta biyaha ee awoodda weyn, si buuxda u hubi qaboojinta wareegga, awoodda bamka qaboojinta: 0.48kW, cadaadiska: 3bar.

Wejiga madaxa waxa lagu rakibay biro qaboojin, kuwaas oo noqon kara biyo ama hawo la qaboojiyo oo la beddelo marka la doono. Habka qaboojinta waxaa xakameyn kara M code ama guddiga kontoroolka.

Ku qalabaysan qoriga hawada lagu nadiifiyo si loogu nadiifiyo qalabka mashiinka.

6. Nidaamka sambabada

Saddex-geesoodka pneumatic-ka ayaa sifeyn kara wasakhda iyo qoyaanka isha hawada si looga hortago burburka iyo daxalka qaybaha qalabka mishiinka. Kooxda waalka solenoid-ka waxa gacanta ku haysa barnaamijka PLC si loo hubiyo in dunta dunnidu ay dabacsan tahay, xarunta dunidu afuufto, mindida dunta dunta dunta lagu xidho, qaboojinta dunta dunta iyo ficilada kale si degdeg ah oo sax ah loo dhamaystiro.

7. Habka saliidaynta

Xadiidka hagaha iyo biraha kubbadda waxaa si toos ah loogu subkay saliid dhuuban oo dhexe. Node kasta waxaa lagu qalabeeyaa qaybiyaha saliidda tirada, kaas oo waqtiyeysan oo lagu qiyaaso qaybaha saliidda leh si loo hubiyo in sifeynta isku midka ah ee dusha sare ee simbiriirixan kasta, si wax ku ool ah u yareyso iska caabbinta iska caabinta, hagaajinta saxnaanta dhaqdhaqaaqa, iyo hubinta nolosha adeegga kubbadda birta iyo hagaha.

8. Ilaalinta qalabka mashiinka

Mashiinku wuxuu qaataa qolka ilaalinta badbaadada, kaas oo aan ka hortagayn oo keliya qulqulka qaboojiyaha, laakiin sidoo kale wuxuu hubinayaa hawlgalka badbaadada leh iyo muuqaalka wanaagsan. Xadiidka hage kasta ee qalabka mishiinku waxa uu leeyahay dabool ilaalin ah oo ka hortagaya in chips iyo qaboojiyaha ay soo galaan gudaha qalabka mishiinka oo ay uga hortagaan xadiidka hagaha iyo biraha kubbada inay xidhmaan iyo daxalka.

9. Habka saarista jajabka (ikhtiyaar)

Dhidibka Y ee qaab-dhismeedka difaaca ee kala qaybsan wuxuu ka dhigayaa jajabyada birta ah ee lagu soo saaro habka hab-socodka si toos ah ugu soo dhacaan sariirta, iyo qaabka weyn ee u janjeera gudaha sariirta ayaa ka dhigaysa jajabyada birta inay si habsami leh ugu simbiriiraan saxanka silsiladda qalabka dheecaanka silsiladda ee hoose ee qalabka mashiinka. Saxanka silsiladda waxaa wada matoorka dareeraha ee chips-ka, waxaana chips-yada loo qaadaa baabuurka sii daayo chip-ka.

Aaladda dajinta silsilada waxay leedahay awood gudbin oo weyn, qaylo yar, qalabka ilaalinta xad dhaafka ah, hawlgal badbaado leh oo la isku halayn karo, waxaa loo isticmaali karaa noocyo kala duwan oo ah qashinka iyo gariiradda.

Sharaxaada Alaabta

Tilmaamaha

| Qaabka | VMC850L | Unug | ||

| Miiska shaqada | Cabbirka shaqada | 1000×500 | mm | |

| Max. culeyska culeyska | 600 | kg | ||

| Cabbirka booska T | 18×5 | mm× Cutub | ||

| Baaxadda habaynta | Max. safarka miiska - X-dhidibka | 800 | mm | |

| Max. safarka slide - Y dhidibka | 500 | mm | ||

| Max. safarka dunta - Z dhidibka | 500 | mm | ||

| Fogaanta laga bilaabo cidhifka dhabarka wejiga ilaa miiska shaqada | Max. | 650 | mm | |

| Min. | 150 | mm | ||

| Fogaanta u jirta xarunta lafdhabarta ilaa saldhigga tareenka | 560 | mm | ||

| Spinal | Taper (7:24) | BT40 |

| |

| Kala duwanaanshaha xawaaraha | 50-8000 | r/min | ||

| Max. wax soo saarka | 48 | Nm | ||

| Spindle power motor | 7.5/11 | kW | ||

| Habka wadista Spindle-ka | Suunka iliga oo isku mid ah |

| ||

| Qalab | Qaabka gacanta qalabka | MAS403 BT40 |

| |

| Jiid model cidiyaha | MAS403 BT40-I |

| ||

| Quudinta | Dhaqdhaqaaq degdeg ah | dhidibka X | 24 (36) | m/min |

| dhidibka Y | 24 (36) | |||

| dhidibka Z | 24 (36) | |||

| Awooda saddexda dhidib ee wadista wadista (X/Y/Z) | 2.3/2.3/3 | kW | ||

| Wareegga saddexda dhidibka ah (X/Y/Z) | 15/15/23 | Nm | ||

| Heerka quudinta | 1-20000 | mm/min | ||

| Qalab | Foomka joornaalka | Manipulator (Koofiyadaha ikhtiyaariga ah) |

| |

| Habka xulashada qalabka | Xulashada agabka laba jiho ee ugu dhow |

| ||

| Awoodda joornaalka | 24 |

| ||

| Dhererka qalabka ugu badan | 300 | Mm | ||

| Miisaanka qalabka ugu badan | 8 | Kg | ||

| Dhexroorka madaxa ugu sarreeya | Buuxa | Φ78 | Mm | |

| Mindi maran oo ku xiga | φ120 | Mm | ||

| Qalabka beddelka wakhtiga (qalabka ilaa qalab) | 1.8 (Koofiyadda Bamboo 8S) | S | ||

| Meelaynta saxnaanta | JSB6336-4:2000 | GB/T18400.4-2010 |

| |

| dhidibka X | 0.016 | 0.016 | Mm | |

| dhidibka Y | 0.012 | 0.012 | Mm | |

| dhidibka Z | 0.012 | 0.012 | Mm | |

| Ku soo celi saxnaanta meelaynta | dhidibka X | 0.010 | 0.010 | Mm |

| dhidibka Y | 0.008 | 0.008 | Mm | |

| dhidibka Z | 0.008 | 0.008 | Mm | |

| Miisaanka mashiinka | 4800 | Kg | ||

| Wadarta awooda korantada | 20 | KVA | ||

| Cabirka guud (L×W×H) | 2730×2300×2550 | Mm | ||