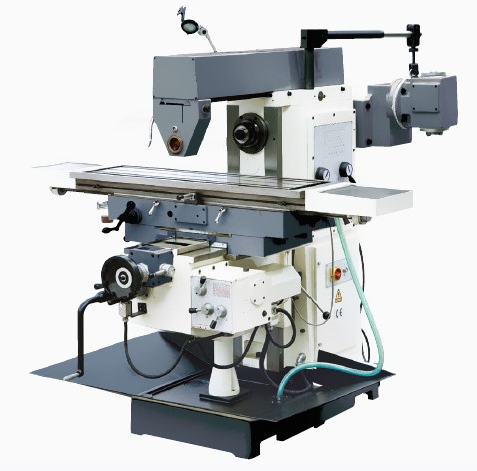

HMC630 Horizontal Machining Center

Astaamaha

- X,Y,Z waxay qaataan hagitaan toosan oo toosan oo culeys badan, hagaajinta qallafsanaanta mashiinka;

- Isticmaalka caalimiga caalimiga ah ee degdega ah ee degdega ah ee aamusnaanta leh waxay hagaajinaysaa saxnaanta meelaynta qalabka mishiinka.

- 60m/min Xawaaraha quudinta degdega ah wuxuu yareeyaa wakhtiga mashiinka wuxuuna wanaajiyaa hufnaanta mashiinka;

- Qalabka mishiinku wuxuu qaataa sariirta isku dhafan ee T-qaabeeya, qaab-dhismeedkuna waa mid macquul ah iyada oo loo marayo falanqaynta walxaha xaddidan ee habka naqshadeynta;

- oo leh Fanuc 0i MF ama nidaamka Siemens horumarsan; xasilooni sare, xawaare degdeg ah;

- Matoorka dhidibka B-axis wuxuu wadaa miiska si uu ugu wareego dhimista qalabka gooryaanka.

- Miis wareeg ah oo leh shaqo tusmeyn toos ah, meelaynta saxanka iliga iyo saxnaanta meelaynta sare.

- Spindle-ku waxa uu qaataa dunta toosan, xawli sare, gariir la'aan, saxnaanta farsamaynta sare

- Wiishka madaxa ayaa qaata dhululubada dheelitirka nitrogen-hydraulic, kaas oo kor u qaadaya xawaaraha jawaabta wiishka;

- Qalabka mashiinka waxaa lagu qalabeeyaa daboolka ilaalinta tareenka ee hagaha, iyo daboolka ilaalinta jihada ee X iyo Y wuxuu qaataa daboolka ilaalinta nooca derbiga ah ee muhiimka ah, kaas oo kor u qaadaya heerka ilaalinta qalabka mashiinka, si wax ku ool ah u ilaaliya tareenka hagaha iyo qulqulka rasaasta, oo kordhiya nolosha adeegga;

- Qalabka mishiinku wuxuu qaataa ilaalin si buuxda u xiran si looga hortago in ay gooyaan dareeraha goynta inta lagu jiro mashiinka degdega ah.

- Nidaamka qalliinka waa saldhig, kaas oo ku habboon isticmaalayaasha si ay u shaqeeyaan oo si weyn u ilaaliya badbaadada wadayaasha.

- Qaybta hore ee mishiinka waxaa ku rakiban albaab kaas oo leh furin weyn si uu u fududeeyo hawlwadeenka inuu beddelo qalabka shaqada.

- Mashiinku wuxuu ku qalabaysan yahay majaladda qalabka caanka ah ee Taiwan, 40pcs Tool magazine, ATC.

- Qalabka mishiinku wuxuu ku qalabaysan yahay nidaam sifeyn toos ah. Waxa gacanta ku haysa PLC madax-bannaan oo si toos ah u qaybisa saliidda iyadoo loo eegayo fogaanta shaqada, taas oo si weyn u yaraynaysa qashinka saliidaha oo ka fogaanaya hoos u dhaca nolosha muraayadda rasaasta iyo hagaha toosan sababtoo ah saliid la'aanta.

- Waxaa jira qalab si toos ah looga saarayo jajabka bartamaha sariirta mashiinka. Gaadhiyaha saxanadda silsiladdu waxay sii daynaysaa jajabyada birta ee dunta ka hoosaysa oo gaadhsiiya gaadhiga nooca saxanka ee dhinaca dambe ee sariirta. Ka dib marka la qaado qalabka nooca saxanka ah ee nooca silsiladda ah, jajabyada birta ayaa lagu ururiyaa ururinta jajabyada Baabuurka, kulaylka haraaga ah ee feylasha birta ayaa si degdeg ah loo qaadayaa, saxnaanta qalabka mishiinkuna waa mid deggan.

17.The hagaha dambe ee sariirta sariirta ayaa lagu tallaabsaday, oo leh hore hoose iyo dhabarka sare, iyo farqiga dhererka weyn, taas oo aan yarayn karin oo kaliya miisaanka qaybaha dhaqdhaqaaqa (tirarka) iyo hagaajinta xawaaraha jawaabta qalabka mashiinka, laakiin sidoo kale waxay ka hortagtaa daqiiqadaha gadaashiisa ee qalabka mashiinka inta lagu jiro jarida iyo hagaajinta xasiloonida mashiinka mashiinka mashiinka.

Tilmaamaha

| Qaabka | HMC630 | Unug | ||

| Shaxda | Cabbirka miiska | 630×630 | mm | |

| tiro | 1 | pc | ||

| Max. raran | 1200 | Kg | ||

| Shaxda | T Afyare | mm | ||

| Unugga qaybinta ugu yar | 1° | shahaadada | ||

| Xawaaraha ugu sarreeya ee leexashada

| 16.7 | rpm | ||

| Kala duwanaanshaha mashiinka | Safarka safka ugu badan - dhidibka X | 1100 | mm | |

| Safarka ugu badan ee madax - dhidibka Y | 900 | mm | ||

| Safarka ugu badan ee miiska - dhidibka Z | 1000 | mm | ||

| Dhexroor leexashada ugu badan ee workpiece | 1000 | mm | ||

| Fogaanta dhidibka dunta ilaa miiska shaqada | Max. | 950 | mm | |

| Min. | 50 | mm | ||

| Fogaanta bartamaha miiska ilaa cidhifka hore ee dunta dunta | Max. | 1200 | mm | |

| Min. | 200 | mm | ||

| Spinal

| Taper (7:24) | BT50 | ||

| Xawaaraha ugu sarreeya | 10000 | r/min | ||

| Max. Qulqulka soo baxay | 260 | N·m | ||

| u adkeyso caabbinta axial ugu badan | 18000 | N | ||

| Awoodda matoorka | 22 | Kw | ||

| quill dia. | Φ190 | mm | ||

| max garaacista dia | tuurid | M20 | mm | |

| Birta Kaarboonka | M16 | |||

| Nidaamka quudinta | X, Y, Z servo motor power | 7 | Kw | |

| dhidibka B servo awoodda motor | 4 | Kw | ||

| Goynta qiyaasta xawaaraha quudinta | 1-12000 | mm/min | ||

| Quudinta degdega ah | X | 60000 | mm/min | |

| Y | 60000 | |||

| Z | 60000 | |||

| Majaladda qalabka

| nooca | Nooca manipulator | ||

| kartida | 20/24 | kumbiyuutarada | ||

| Max. Qalabka dia. | 125/250 | mm | ||

| Max. Dhererka qalabka | 400 | mm | ||

| Max. Miisaanka qalabka | 25 | kg | ||

| Wakhtiga beddelka qalabka (qalabka-qalabka) | 4.7 | s | ||

| Meelaynta saxnaanta

| Heerka GB/T 18400.4 | X | 0.008 | mm |

| Y | 0.008 | |||

| Z | 0.008 | |||

| B | 8 | arcsec | ||

| Ku soo celi saxnaanta meelaynta

| Heerka GB/T 18400.4 | X | 0.004 | mm |

| Y | 0.004 | |||

| Z | 0.004 | |||

| B | 2 | arcsec | ||

| Kontoroolka Cnc | nooca | FANUC 0i MF (1)

| ||

| Wadarta tirada faasaska la kantaroolo | 5 | Faasas | ||

| Tirada faashashka xakamaynta isku xirka | 4 | Faasas | ||

| Shuruudaha korontada | Shuruudaha Awoodda | 50KVA, 3ph, 380V,50HZ | ||

| Shuruudaha isha hawada | 0.5-0.7MPa | |||

| Cabirka

| Dhererka | 6300 | mm | |

| Ballaca | 4300 | mm | ||

| Dhererka | 3500 | mm | ||

| Miisaanka mashiinka | 16000 | Kg | ||

Halkan ku qor fariintaada oo noo soo dir